UP (Unsaturated polyester resins): Properties, Applications, and Sustainability

Unsaturated polyester resins (UP) are versatile thermosetting polymers widely used in the plastics industry for their excellent mechanical, chemical, and electrical properties. They have a long history, dating back to the 1930s, and have found applications in various industries such as transportation, construction, and electrical & electronics. However, the use of UP also presents challenges, such as limited recyclability and susceptibility to UV degradation.

The first commercial production of UP began in the 1940s. Initially used in boat building, its usage rapidly expanded to various other industries, such as automotive, construction, and electronics.

What is Unsaturated Polyester Resin (UP)?

Unsaturated Polyester Resin (UP) is a thermosetting polymer made from the reaction of a saturated dibasic acid (such as maleic anhydride) and an unsaturated diol (such as propylene glycol). It is called “unsaturated” because double bonds in the polymer chain can be used for further cross-linking with a reactive monomer, such as styrene.

Properties of UP

UP has several desirable properties that make it a popular material in various applications. These properties include:

- High strength and stiffness

- Good chemical resistance

- Low cost

- Excellent dimensional stability

- Easy to process and shape

- Good electrical insulation properties

Industrial Usage of UP

UP is used in many industries due to its excellent properties. Some of the standard industrial applications of UP include:

- Marine and automotive industries – UP is widely used in the construction of boats, yachts, and automobile parts because of its excellent dimensional stability, low weight and good mechanical properties.

- Construction industry – UP is used in the manufacturing of prefabricated houses, pipes, tanks and other structural components. It is ideal for these applications due to its high strength, stiffness, and weather resistance.

- Electrical and electronics industry – UP is used in the manufacturing of electrical components such as transformers, capacitors and insulators due to its excellent electrical insulation properties.

Application Areas of UP

UP is used in various application areas because of its desirable properties. Some of the common application areas of UP include:

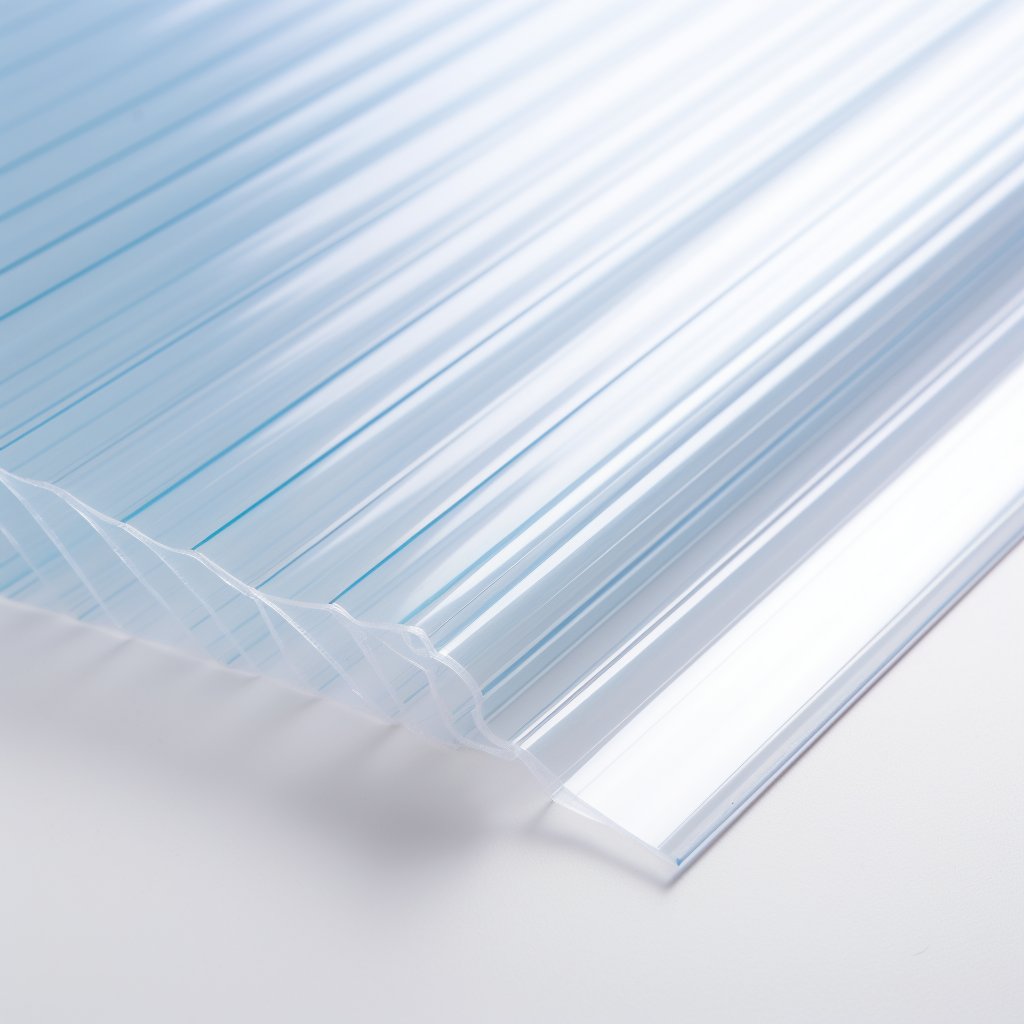

- Construction – UP is used to manufacture building materials such as roofing sheets, pipes, and panels.

- Transportation – UP is used in the manufacturing of automotive parts, aircraft components, and railway components.

- Electrical and Electronics – UP is used in the manufacturing of electrical components such as transformers, capacitors, and insulators.

- Packaging – UP is used in the manufacturing of packaging materials such as bottles, cans, and containers.

Consumer Product Examples of UP

UP is also used in consumer products due to its low cost, easy processing and excellent properties. Some of the typical consumer product examples of UP include:

- Bathroom fixtures – UP is used in the manufacturing of bathroom fixtures such as sinks, shower trays, and bathtubs.

- Furniture – UP is used in the manufacturing of furniture such as chairs, tables, and cabinets.

- Sports equipment – UP is used in the manufacturing of sports equipment such as surfboards, skis, and helmets.

Recycling of UP

UP is not easily recyclable due to the cross-linking reaction that occurs during its curing process. However, UP can be recycled through a mechanical or chemical process. The mechanical process involves grinding the cured UP into small particles, which can be used as a filler in new UP products. The chemical process involves breaking down the cured UP into its constituent monomers, which can be used to produce new UP products.

Recycling is an important aspect of sustainable use of UP. Although UP is not easily recyclable due to the cross-linking reaction that occurs during its curing process, it can be recycled through a mechanical or chemical process.

Mechanical Recycling of UP

The mechanical process involves grinding the cured UP into small particles, which can be used as a filler in new UP products. The recycled UP can be used to manufacture products such as fibreglass reinforced plastics (FRP) sheets, roofing tiles, and automotive parts. Mechanical recycling of UP has the following advantages:

- It reduces the amount of UP waste going to landfills.

- It reduces the consumption of virgin materials.

- It saves energy and reduces greenhouse gas emissions associated with producing virgin materials.

However, there are also some disadvantages of mechanical recycling of UP, such as:

- The recycled material may have inferior properties compared to the virgin material.

- The recycling process can be expensive and energy-intensive.

Chemical Recycling of UP

The chemical process involves breaking down the cured UP into its constituent monomers, which can be used to produce new UP products. The chemical recycling of UP has the following advantages:

- It produces high-quality monomers that can be used to manufacture new UP products.

- It reduces the consumption of virgin materials.

- It saves energy and reduces greenhouse gas emissions associated with the production of virgin materials.

However, there are also some disadvantages of chemical recycling of UP, such as:

- The recycling process can be expensive and energy-intensive.

- The recycled material may have inferior properties compared to the virgin material.

- The recycling process may generate hazardous waste.

Environmental and Global Impact of UP Recycling

Recycling UP has positive environmental and global impacts as it reduces the amount of waste going to landfills, conserves resources, saves energy, and reduces greenhouse gas emissions associated with the production of virgin materials. The recycling of UP also helps to address the problem of plastic pollution, which is a global concern.

In addition, developing new technologies and processes to improve the recyclability of UP could contribute to the transition towards a circular economy, where waste is minimized, resources are conserved, and environmental impact is reduced. Therefore, it is important to promote the recycling of UP and to invest in research and development to improve the recyclability of this material.

Advantages and Disadvantages of UP Compared to Alternative Plastics

UP has several advantages compared to alternative plastics, such as:

- High strength and stiffness

- Good chemical resistance

- Low cost

- Excellent dimensional stability

- Easy to process and shape

- Good electrical insulation properties

However, there are also some disadvantages of UP compared to alternative plastics, such as:

- Limited temperature resistance

- Brittleness at low temperatures

- Susceptibility to moisture absorption

- Susceptibility to UV degradation

- Limited recyclability

Market Price Developments and Future Market Prognosis

The global UP market is projected to grow at a CAGR of 6.5% from 2021 to 2026, driven by increasing demand from end-use industries such as transportation, construction, and electrical & electronics. Several factors, such as raw material prices, demand-supply dynamics, and technological advancements influence the market price of UP.

The price of UP has remained relatively stable in recent years, but it is expected to increase in the future due to rising raw material prices and increasing demand. The development of new technologies and processes to improve the recyclability of UP could also influence its market price.

In conclusion, UP is a widely used thermosetting polymer with several advantages and disadvantages compared to alternative plastics. Its usage has expanded to various industries, and the global UP market is expected to grow in the future. However, UP’s limited recyclability is a major challenge that needs to be addressed to ensure the sustainable use of this material.

Unsaturated Polyester Resin (UP)

Unsaturated Polyester Resin (UP) is a widely used thermosetting polymer due to its excellent properties, low cost, and easy processing. Its usage has expanded to various industries, including marine, automotive, construction, and electronics. UP is also used in the manufacturing of consumer products such as bathroom fixtures, furniture, and sports equipment. While UP offers many advantages, such as excellent mechanical, chemical, and electrical properties, the challenges of limited recyclability and susceptibility to UV degradation remain a concern. Therefore, the need to promote sustainable use of UP and reduce plastic waste is more urgent than ever.

Fortunately, there are several recycling methods for UP, such as mechanical and chemical recycling, that can help minimize its environmental impact and contribute to a circular economy. Additionally, innovation and investment in research and development can further improve the properties and recyclability of UP, making it a more sustainable and valuable material in the future.